puraidodes

Well-Known Member

- Messages

- 135

- Likes

- 75

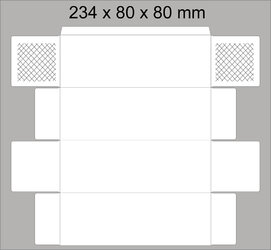

Could someone please explain this to me?

I'm a bit confused since I'm new at this. I'm skilled in design, but I'm a beginner in print and packaging.

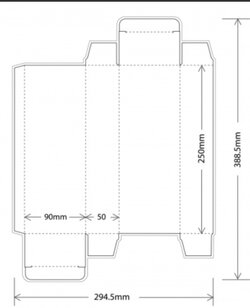

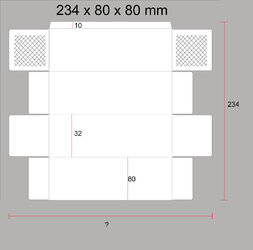

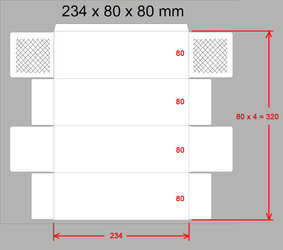

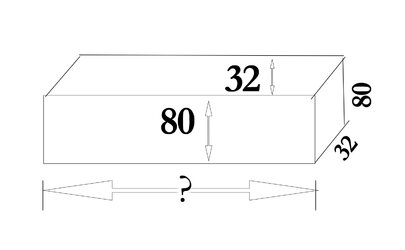

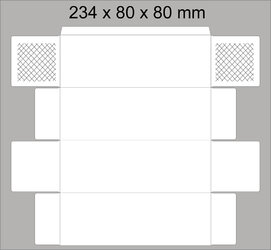

I understand the basics of cut and die lines, bleed, safe, the gluing regions, but I'm not sure where to measure the length, width, and height.

Are the measurements provided for individual sides or for the entire package? In my previous designs, the measurements were clearly specified for each side and flap, unlike this.

I'm feeling a bit lost here. Unfortunately, I can't decline this task. Could someone explain it a bit further? Thanks!

I'm a bit confused since I'm new at this. I'm skilled in design, but I'm a beginner in print and packaging.

I understand the basics of cut and die lines, bleed, safe, the gluing regions, but I'm not sure where to measure the length, width, and height.

Are the measurements provided for individual sides or for the entire package? In my previous designs, the measurements were clearly specified for each side and flap, unlike this.

I'm feeling a bit lost here. Unfortunately, I can't decline this task. Could someone explain it a bit further? Thanks!